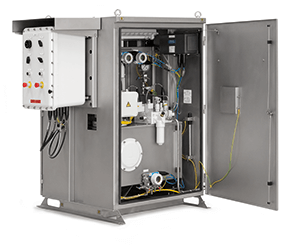

Explosion-proof hydraulic systems for loading arms generally consist of a HPU which generates the hydraulic power required for the movements, one or more control blocks mounted close to different loading arms, plus storage racks that guarantee the release and retraction of the arm in emergency conditions.

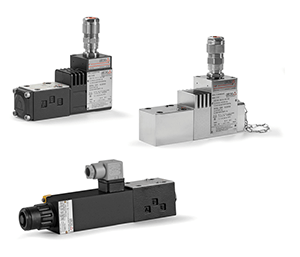

Loading arm functions such as the Emergency Release System (ERS) and the Quick Connect / Disconnect Couplers (QC/DC) are operated via explosion-proof on/off solenoid valves while, the three-axis arm movement phases, typically inboard, outboard and swiveling, are performed by ex-proof proportional valves which allow a wobble-free linear control and real-time speed variation, resulting in simpler and safer maneuvering with a reduction of connection and disconnection times form the vessel.

The explosion-proof hydraulic systems are designed to be installed in hazardous areas up to zone 1 and certified according to ATEX and IECEx directives. In order to ensure high corrosion resistance, cabinets are typically designed with 316L stainless steel protection, but also carbon steel materials can be used applying a C5-M coating cycle with 160 ÷ 320 μm thick. In particular for offshore applications, where environmental conditions and minimum temperatures are much more severe, the use of ex-proof stainless steel valves is preferred.

Hydraulic systems and ex-proof stainless steel valves for marine loading arms

ATEX and IECEx certified systems applied to customised and innovative solutions for onshore and offshore transfer systems

Atos provides innovative electro-hydraulic systems for marine loading arms for onshore and offshore use with several applications in the Oil & Gas industry. Customized hydraulic solutions include ex-proof stainless steel valves, global equipment certifications such as ATEX and IECEx, and ex-proof proportionals with on-board digital electronics with optional fieldbus communications.

INDEX

Loading arms: essential systems for loading and unloading operations in oil terminals

Explosion-proof hydraulic systems and ex-proof stainless steel valves for loading arms

Atos, the widest range of explosion-proof hydraulic components and systems with ATEX and IECEx certification

Contact Us

Loading arms: essential systems for loading and unloading operations in oil terminals

Loading arms are devices used to load or unload oil or gas from tankers or storage stations. They can be installed on a fixed structure such as a refinery or oil terminal (onshore systems) or on offshore platforms.

Designed to facilitate safe and efficient loading/unloading without leakage or safety hazards, they can rotate and extend to serve different vessels sizes.

In order to be able to monitor and manage the internal loading/unloading process safely, loading arms must meet oil and gas industry stringent requirements using only explosion-proof devices with high reliability and corrosion resistance, such as ex-proof stainless steel valves certified to operate in hazardous environments according to applicable international standards.

Explosion-proof hydraulic systems for marine loading arms are therefore a highly safe solution, as they are designed to prevent the risk of sparks, fires or explosions in potentially explosive environments, as like flammable liquids storage areas. Thanks to the use of explosion-proof digital proportional valves, these systems are able to precisely control arm movements, ensuring reliable control and reducing the risk of fluid spills or leaks during docking maneuvers. Furthermore, ex-proof hydraulic devices marked ATEX and IECEx standards ensures full compliance with international regulations on safety and protection against explosive mixtures.

In order to be able to monitor and manage the internal loading/unloading process safely, loading arms must meet oil and gas industry stringent requirements using only explosion-proof devices with high reliability and corrosion resistance, such as ex-proof stainless steel valves certified to operate in hazardous environments according to applicable international standards.

Explosion-proof hydraulic systems for marine loading arms are therefore a highly safe solution, as they are designed to prevent the risk of sparks, fires or explosions in potentially explosive environments, as like flammable liquids storage areas. Thanks to the use of explosion-proof digital proportional valves, these systems are able to precisely control arm movements, ensuring reliable control and reducing the risk of fluid spills or leaks during docking maneuvers. Furthermore, ex-proof hydraulic devices marked ATEX and IECEx standards ensures full compliance with international regulations on safety and protection against explosive mixtures.

Explosion-proof hydraulic systems and ex-proof stainless steel valves for loading arms

Hydraulic power unit for loading arms

Hydraulic power unit for loading arms

Atos, the widest range of explosion-proof hydraulic components and systems with ATEX and IECEx certification

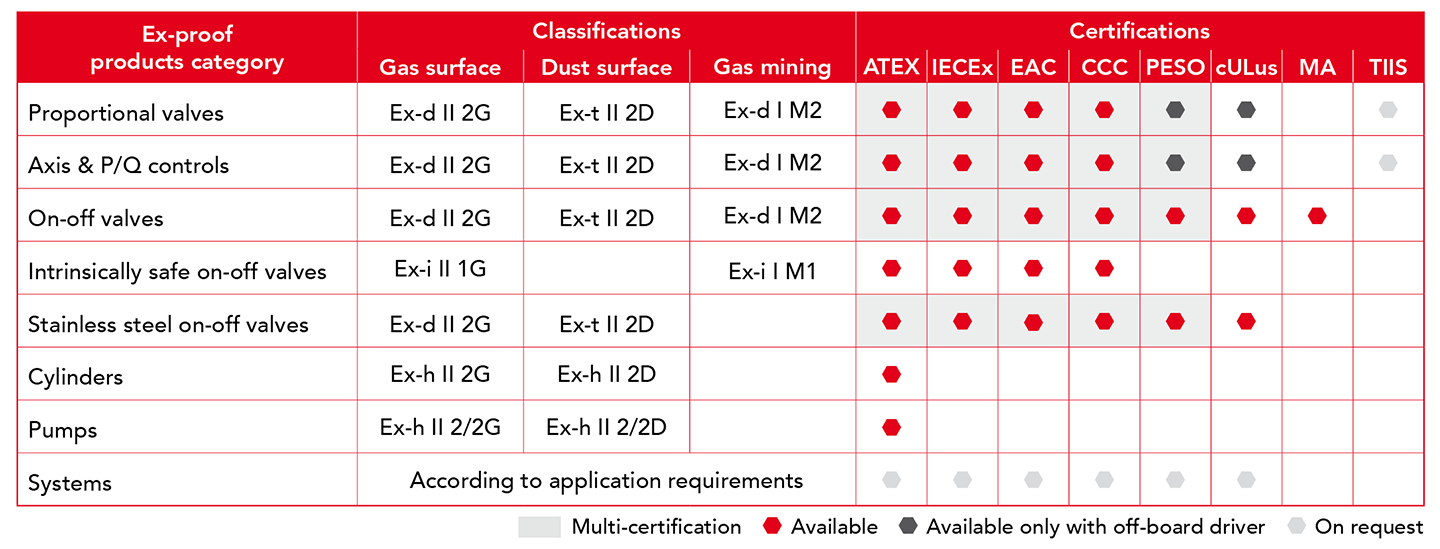

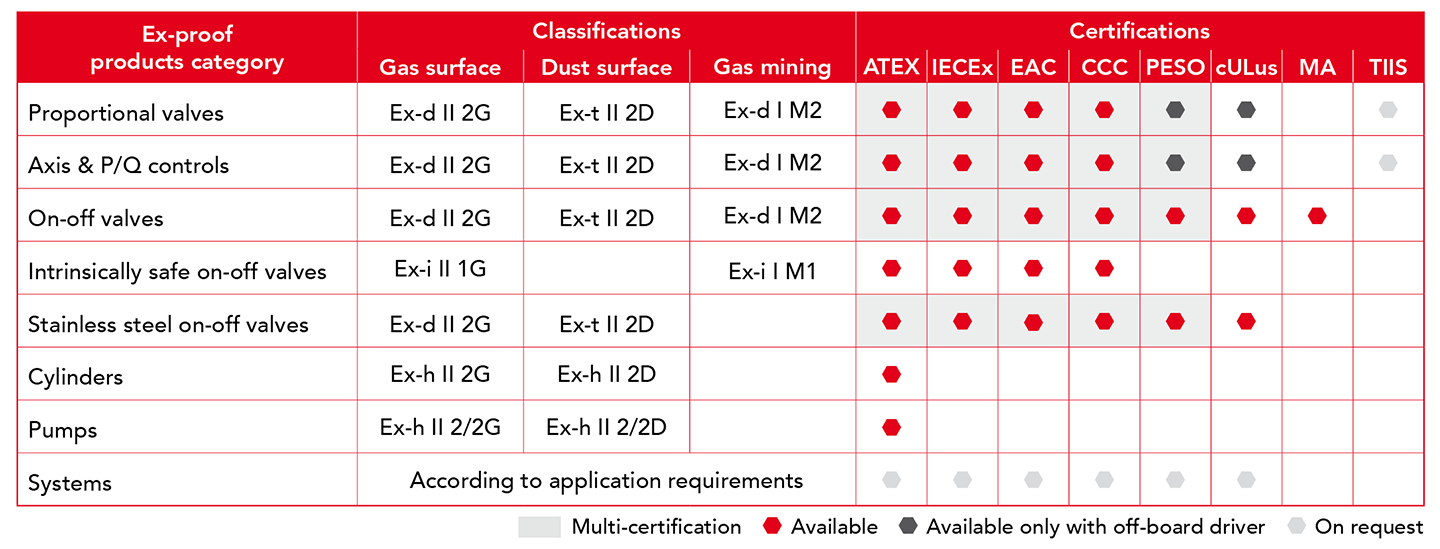

The classification of potentially explosive areas within refineries, oil terminals or offshore platforms can vary depending on the type of fluid/gas processed and the installation location. Generally, loading arms are installed in Zone 1, which requires Ex-d ex-proof stainless steel valves associated with Ex-h actuators and pumps, to prevent any hazards caused by hot surfaces or moving mechanical parts.

Atos offer the widest range of multi-certified hydraulic components for hazardous environments, from on-off valves to complete systems.

Atos offer the widest range of multi-certified hydraulic components for hazardous environments, from on-off valves to complete systems.

Atos ex-proof hydraulics certifications

The ex-proof on-off valves are certified to operate up to Zone 1 and 21, while intrinsically safe on-off valves offer the highest protection level in environments with very high-risk of explosion, up to Zone 0. Ex-proof stainless steel valves provide maximum resistance to low temperatures, corrosive environments and fluids.

The ex-proof range includes specific executions aimed to further increase the safety level in hazardous environments, such as explosion-proof solenoid valves with certification up to SIL2/SIL3 according to IEC 61508. Explosion-proof proportional valves with integrated digital electronics enable the application of smart solutions designed for industry, even in hazardous areas. As like industrial ethernet and fieldbuses, advanced diagnostics with built-in oscilloscope, high-performance axis and p/Q control.

The ex-proof range includes specific executions aimed to further increase the safety level in hazardous environments, such as explosion-proof solenoid valves with certification up to SIL2/SIL3 according to IEC 61508. Explosion-proof proportional valves with integrated digital electronics enable the application of smart solutions designed for industry, even in hazardous areas. As like industrial ethernet and fieldbuses, advanced diagnostics with built-in oscilloscope, high-performance axis and p/Q control.

Explosion proof on-off valves

Explosion proof on-off valves

Stainless steel power units and hydraulic valves, carbon steel internal parts protected with C5M special marine painting, nitrogen pressurized sealed cabinets and NEK606 electrical wirings are only some of the key factors making Atos Systems Division the preferred hydraulic partner for ATEX and IECEx classified marine environments. Explosion-proof hydraulic power units, specifically designed for hazardous marine environments, are certified by notify bodies such as TÜV, DEKRA, UL,CSA, ABS, BV, DNV GL, RINA.

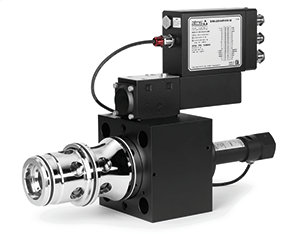

Explosion proof proportional valve

Explosion proof proportional valve

Contact us

Are you interested in Atos explosion-proof hydraulic products?

Do not hesitate to contact us!

Follow us on LinkedIn to stay updated on our activities and products.

Do not hesitate to contact us!

Follow us on LinkedIn to stay updated on our activities and products.