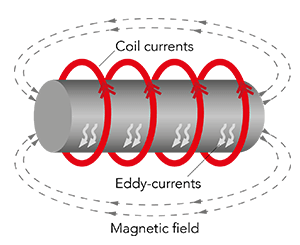

Magnetic induction allows energy to be transferred safely and efficiently from a coil to any ferromagnetic material; the energy transferred to the target is transformed into heat, directly generated in the metal itself.

This allows to maximize the heating performance compared to any other method, thus avoiding energy waste.

Inductive molds preheating: no more open flames inside plant

A safe mold heating method for metal forming

Metal forming is an ever-changing world, with innovations in materials and alloys that lead to new requirements in production processes. However, molds preheating is often still carried out with obsolete and unsafe techniques. Atos Induction, a specialist in induction heating, overcomes this limitation by offering a patented system for inductive mold heat methods.

INDEX

Traditional mold heating methods

The principle of electromagnetic induction

Inductive technology in molds preheating

Contact Us

Traditional mold heating methods

Molds preheating require continuous supervision of specialised personnel and they have several safety disadvantages:

- Induction furnaces require the risky handling of heavy & hot molds from the furnaces. Besides, induction furnaces are bulky and very expensive

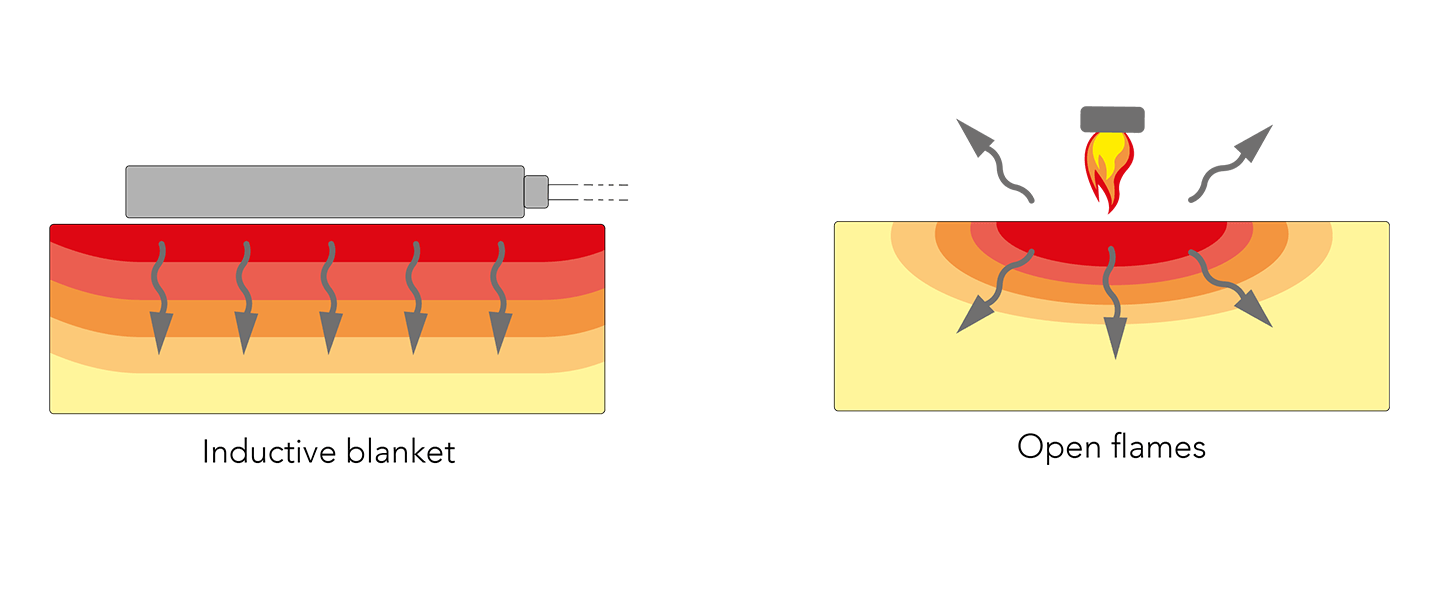

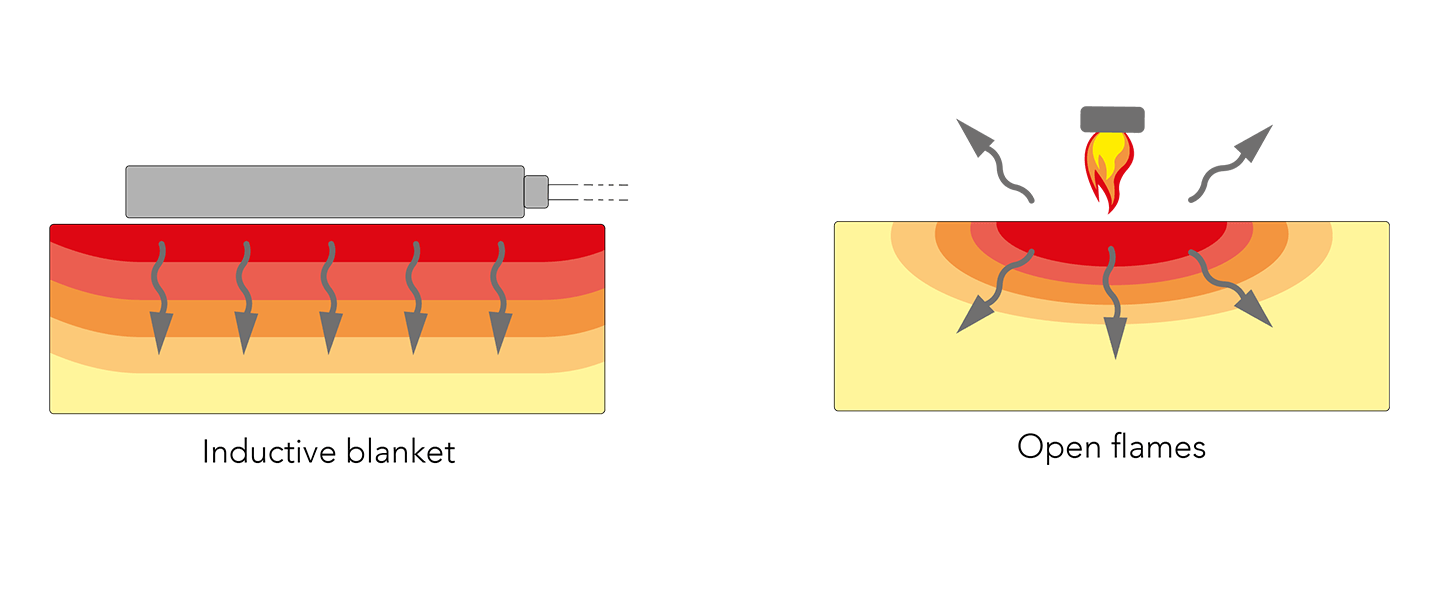

- Open flame burners present enormous dangers related to the use of combustible gases in indoor environments and it doesn’t allow an uniform mold heating

The principle of electromagnetic induction

Illustration of the magnetic induction principle

Illustration of the magnetic induction principle

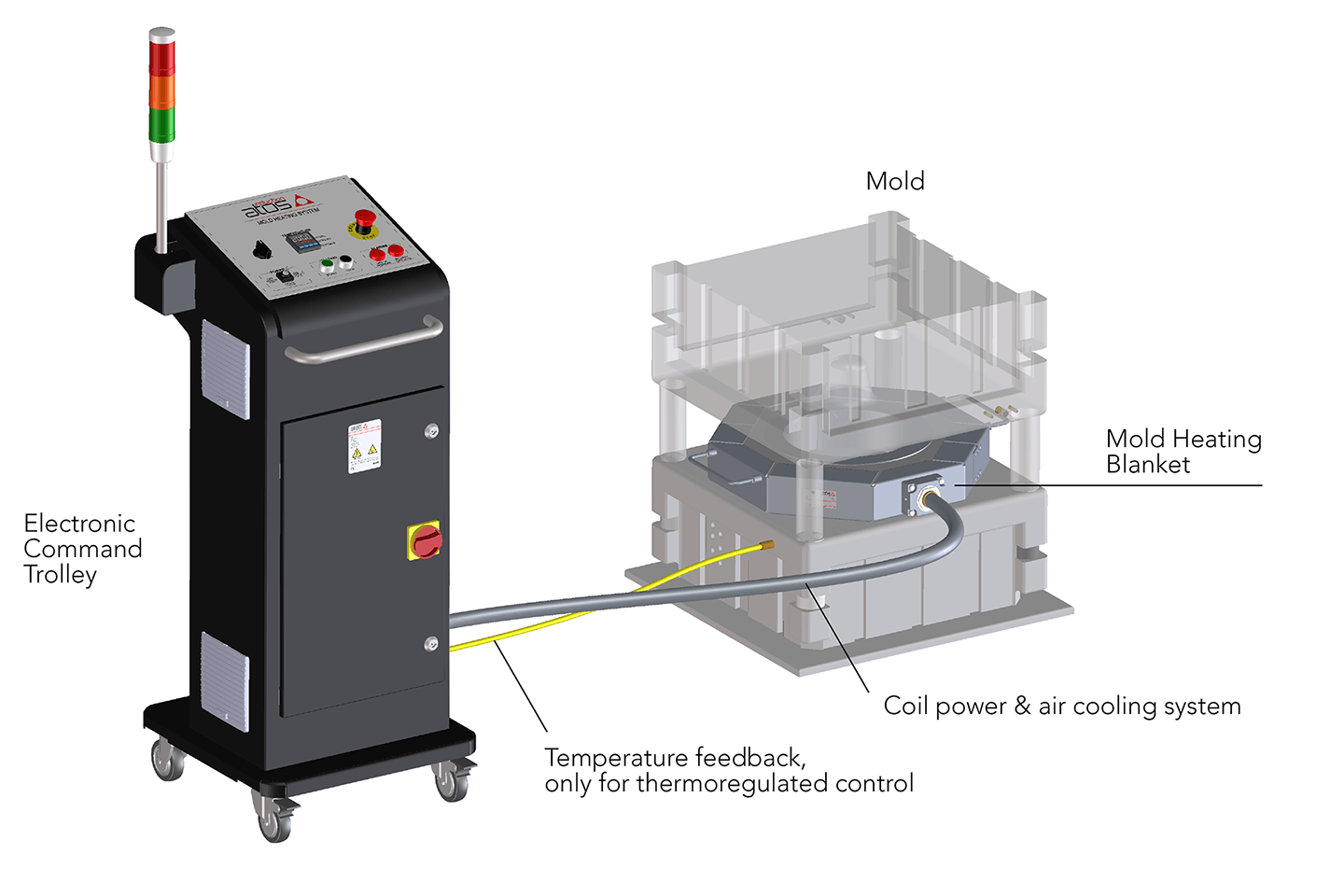

Inductive technology in molds preheating

Atos Induction has exploited the benefits of magnetic induction to create a patented innovative induction heating method dedicated to metal forming.

The induction molds preheating system consists of a flat coil, powered by a control system which manages the heating process.

The induction molds preheating system consists of a flat coil, powered by a control system which manages the heating process.

The Atos Induction molds

preheating system

preheating system

This solution overcomes all the disadvantages of traditional heating methods, through the safe use of induction heating blankets:

- Reduced heating time, thanks to the absence of thermal inertia on heating transfer

- Energy saving because of intrinsic induction high efficiency

- Maximum heating uniformity achieved by generating heat directly inside the material

- Automatic timed or thermoregulated mold heating control, without the need of operator supervision

- Easy to use, no specific skills requested by the user. Simply place the blanket in contact with the surface of the mold and start heating

- Maximum safety during heating operations, eliminating the use of combustible gases and open flames

Comparison of heat

transfer during molds

preheating

transfer during molds

preheating

Atos Induction’s patent, presents an innovation in the field of occupational safety for the molding industry, making it possible to eliminate the use of hazardous and increasingly expensive combustible gases.

Contact us

Are you interested in Atos Induction’s mold heat method?

Do not hesitate to contact us!

Follow us on LinkedIn to stay updated on our activities and products.

Do not hesitate to contact us!

Follow us on LinkedIn to stay updated on our activities and products.