Are you interested in Atos hydraulic filters?

Do not hesitate to contact us!

Follow us on LinkedIn to stay updated on our activities and products.

Hydraulic filters for extended machinery operative life

Atos F+ microfiber filters contribute to the total system approach to fluids cleaning aimed to prevent machine downtime and related costs, improve energy efficiency, with a focus on eco-sustainability

A comprehensive approach to fluid cleaning involves an accurate analysis of the maximum acceptable contamination class, achieved with an appropriate selection of hydraulic filters with the aim of extending component life, improving production times, minimizing downtime and maintenance costs, and, last but not least, reducing waste oil disposal costs with the associated environmental benefits. Microfiber filter elements with absolute filtration capacity can reduce the contamination level at very low values compatible with the most sensitive components.

INDEX

Money lost every year for uncorrect filtration care

Fluid contamination

Hydraulic filters

Filter elements

Atos F+ elements

High Efficiency

Contact Us

Money lost every year for uncorrect filtration care

Analyses conducted in various industrial sectors confirm that an accurate selection of hydraulic filters and filtration methods may reduce the cost for machine downtime, component repairing and fluid disposal of about 50% per year, compared to systems conducted without a specific filtration care.

This aspect is even more important the higher the performance level of the machine and therefore the more sophisticated the components used in the hydraulic circuit.

This aspect is even more important the higher the performance level of the machine and therefore the more sophisticated the components used in the hydraulic circuit.

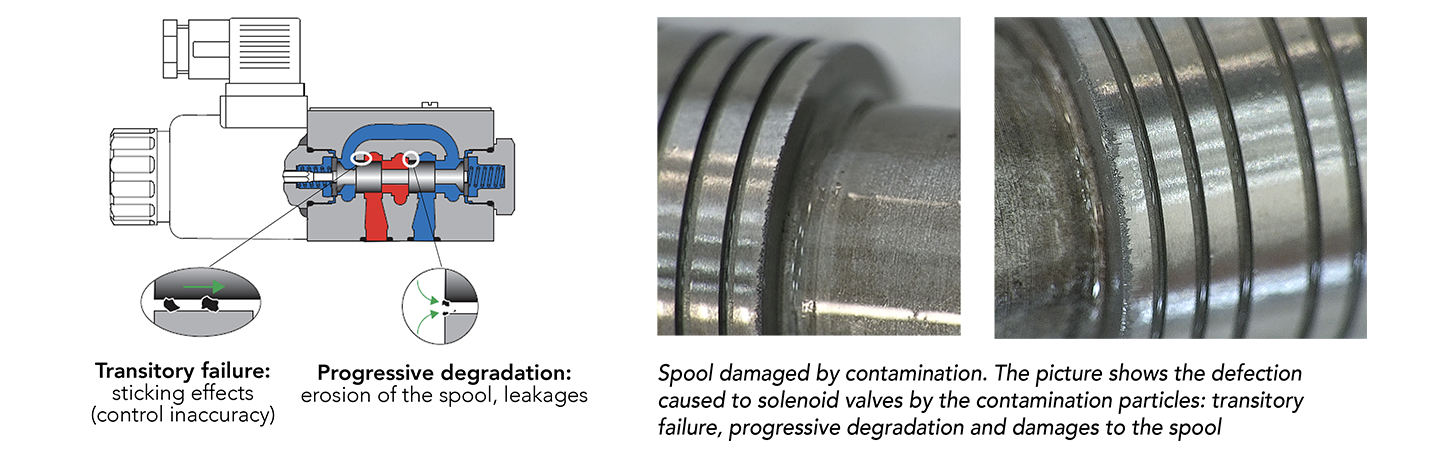

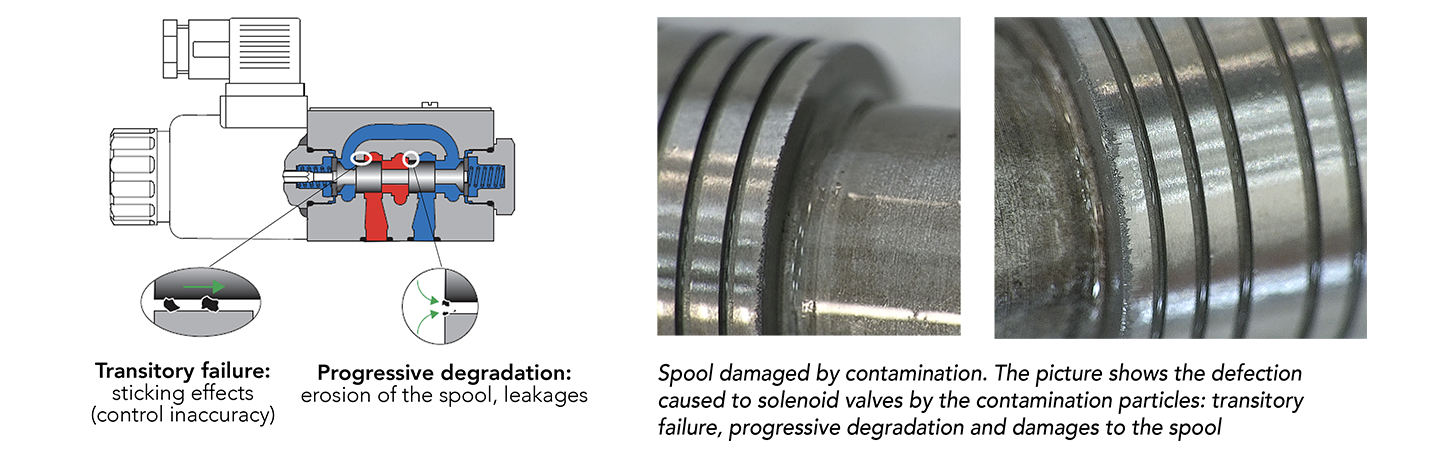

Fluid contamination

Solid contamination of hydraulic fluid is the major cause loss of money as it causes erosion and sticking phenomena of internal parts of pumps, valves and actuators with harmful effects on component’s life.

Solid contamination cannot be completely removed, but it can be consistently reduced by means of hydraulic filters so that its value results equal or better than max contamination level tolerated by the most sensitive component present in the system.

Hydraulic filters

The Return line filter is a cost-effective solution granting the cleanliness of fluid returning to the tank, often used where no sensitive components are present in the system.

It removes the contaminant released by the system during its function before it returns to the tank. Return filters operate at low pressure (max 8-10 bar) and in most of applications they are directly flanged on the tank (tank-top mounting).

It removes the contaminant released by the system during its function before it returns to the tank. Return filters operate at low pressure (max 8-10 bar) and in most of applications they are directly flanged on the tank (tank-top mounting).

The In line filter is warmly suggested for system equipped with proportional valves, since it protects all hydraulic components downstream the filter and ensures a high cleanliness level of the fluid circulating into the hydraulic system. In line filters are designed to withstand high pressure (usually 350 ÷ 420 bar), they can be installed at the pump outlet or directly flanged on manifolds saving pipes and fittings by reducing overall dimensions.

The combination of in-line + return filters is used to obtain greater benefits to reduce the contamination level.

The off-line filtration performs a continuous cleanliness of the fluid in the tank and is particularly used in case of wide change in system flow, for systems operating for long time in null flow or to improve the fluid cleanliness in

systems already equipped with in-line filter. It is frequent the use in of a heat exchanger to combine filtration and temperature control.

Filter elements

They are the “core” of the filter as the quality of the fluid cleanliness depends on their characteristics.

Microfiber filter elements offer the best performance in terms of filtration rating which can reach very accurate values up to 3 µm, and efficiency up to 99.9%, so they are recommended for all hydraulic systems.

Microfiber filter elements offer the best performance in terms of filtration rating which can reach very accurate values up to 3 µm, and efficiency up to 99.9%, so they are recommended for all hydraulic systems.

Atos F+ elements

Atos filtration Plus are microfiber filter elements which combines different materials and layers specifically arranged to reach the best results in terms of high efficiency, high dirt holding capacity and low pressure drops.

Combined layers in the F+ FILTRATION PLUS Filtration Plus element

High Efficiency

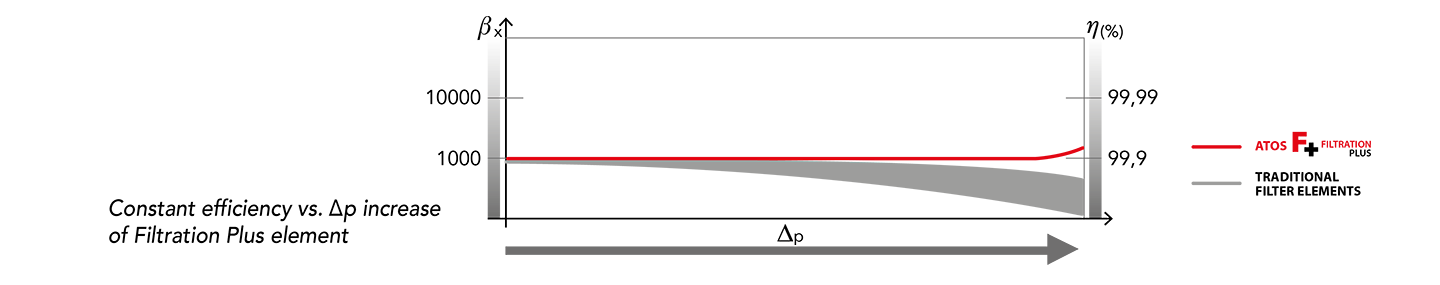

Traditional filter elements reduce their efficiency as the ∆p across the filter increases due to accumulated contaminant. Thanks to their special media pack structure, Atos Filtration Plus elements grants excellent performance in terms of efficiency (Beta Ratio > 1.000) and stability versus pressure drop increase with stable performances for the whole life of the filter element. Furthermore, the reduced pressure drops allow to select a smaller filter for the same application.

The increased Dirt Holding Capacity (D.H.C) of F+ filter elements permits to retain a higher quantity of contaminant before that the max clogging condition is reached. This extends the average life of the filter element, thereby reducing maintenance costs and minimizing the environmental impact for the cartridge disposal.

Such is our confidence about in Filtration Plus microfiber filters elements, that we decided to double the warranty period of all the Atos products present in systems equipped with Atos Hydraulic filters.

Contact us