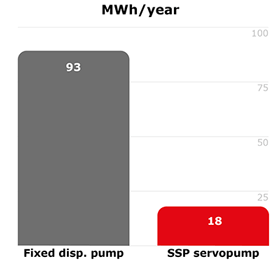

Differently to traditional systems equipped with asynchronous motor that rotates at constant speed generating pressurised oil even when the machine cycle does not require it, servopump delivers hydraulic power only in the quantity necessary to satisfy the work phase being performed.

Comparative analyses, performed on a 300 tons plastic injection molding machine, revealed that the energy consumption of the SSP servopump has been lower than 80 % with respect to fixed displacement pump, leading to annual savings of 75 MWh and 11,7 tons of CO2.

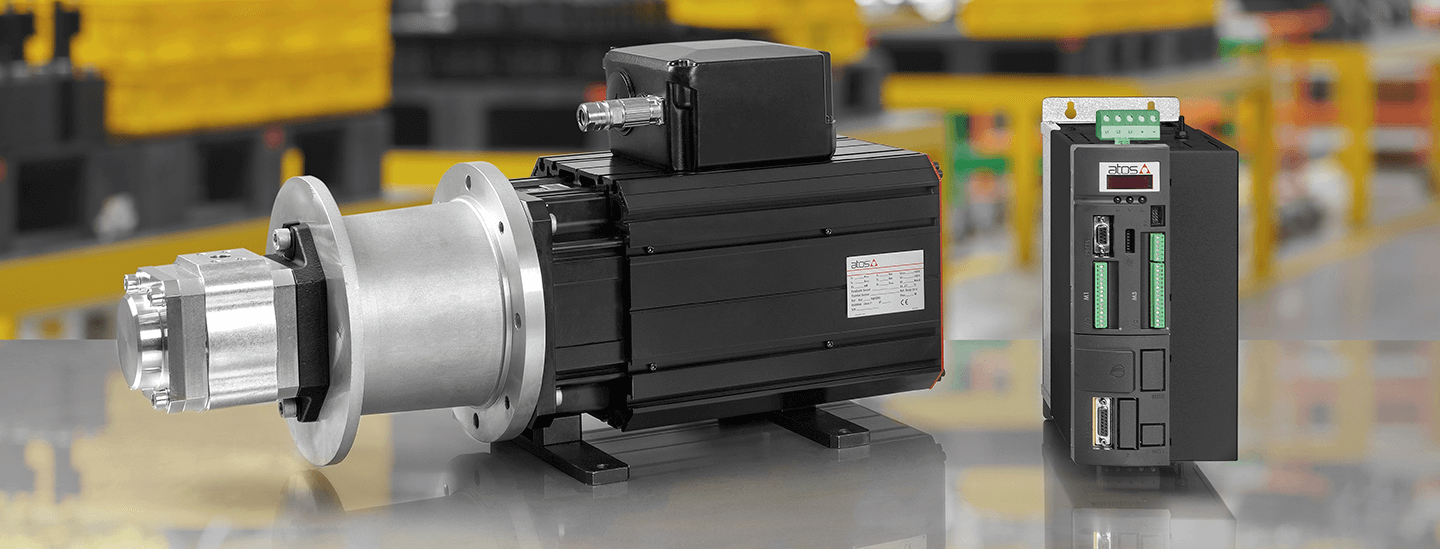

SSP energy saving Smart ServoPump with p/Q control

The most efficient way to generate hydraulic power

The focus on environmental pollution and the current escalation of energy prices is driving markets towards more efficient technologies and solutions. Atos provides the optimal response to market needs thanks to the range of energy saving servopump with p/Q control, capable of saving up to 80%.

INDEX

Energy saving servopump vs traditional systems

The Atos difference

Servopump with p/Q control: much more than energy saving

Contact Us

Energy saving servopump vs traditional systems

Energetic comparison between

Energetic comparison betweenservopump and traditional system

The Atos difference

The Atos R&D department has developed innovative features to let the servopump a simple and straightforward experience.

- Smart Start-up

Smart Start-up feature greatly simplifies the SSP servopump commissioning with a quick and intuitive wizard procedure in order to configure, test and autotune the servopump to obtain the best dynamic response in three simple steps. - Hydraulic p/Q control algorithm

Atos exploited its electrohydraulic know-how to develop a p/Q algorithm dedicated to the control of SSP servopumps and specifically designed for hydraulic axes. Hydraulic machinery manufacturers will be relieved of the development of their own control algorithm. - Autotuning and overheating protection

Modeling and Simulation, together with extensive R&D tests have been the key to develop patented algorithms to simplify SSP servopump commissioning and managing.

Autotuning avoids any need of manual setting, since it performs the automatic parameterization of the servopump to obtain the best dynamic response, ensuring accuracy and stability during the pressure control phases. - Smart cooling

prevents temperature peaks during extended phases of static pressure control. The algorithm estimates the internal temperature of the pump without the use of any transducer. If the temperature exceeds limits, a drain valve for oil recirculation is activated which allows a reduction of pump temperature.

- Multiple hydraulic axis management

SSP control allows the real-time selection of optimal configuration of the axis to be controlled, ensuring the maximum performance for each hydraulic axis of the machine. - Servopump sizing software

The high efficency of servopump allows the downsizing of the hydraulic power unit. The free S-SW-SIZING software leads the user to the selection of most suitable servopump by simply entering the desired machine cycle. Moreover, it also performs an energy estimatation of the system, highlighting the CO2 and operating costs savings of Atos solution compared to conventional systems.

Servopump with p/Q control: much more than energy saving

The angular position transducer integrated into the motor-pump allows to precisely estimate the instantaneous flow rate. Thus, granting higher level of accuracy and repeatability during flow control phases when compared to proportional valves.

The high efficency of SSP system translates in tank downsizing and heat exchanger removal. Moreover, the possibility to reach higher rotational speed allows for pump displacement reduction.

Compared to a variable displacement pump it has a lower noise emission down to 7 dB during flow control phases and 20 dB during pressure control phases, due to low noise emissions of the internal gear pump and the capability to modulate the speed of the motor-pump unit.

The high efficency of SSP system translates in tank downsizing and heat exchanger removal. Moreover, the possibility to reach higher rotational speed allows for pump displacement reduction.

Compared to a variable displacement pump it has a lower noise emission down to 7 dB during flow control phases and 20 dB during pressure control phases, due to low noise emissions of the internal gear pump and the capability to modulate the speed of the motor-pump unit.

Plastic injection machine

Plastic injection machine

Contact us

Are you interested in Atos smart servopump with p/Q control?

Do not hesitate to contact us!

Follow us on LinkedIn to stay updated on our activities and products.

Do not hesitate to contact us!

Follow us on LinkedIn to stay updated on our activities and products.